Backyard Workshop is an unbiased review site. We may earn money when you click on links on our site. Learn more.

Save time and money. Buy Smart.

We do the hard work of researching the best tools for your yard - so you don't have to. Rely on us to get the best tool for your particular job.

Get Answers To All Your How-To and Project Questions

Shop Our Top Picks:

Leaf Blowers

Looking to move a mountain of leaves from your backyard? Our buying guide to the best leaf blowers will help you make the right choice.

Lawn Mowers

Lawn mowers come in all shapes and sizes. From push mowers to robotic lawn mowers, and everything in-between - we have you covered!

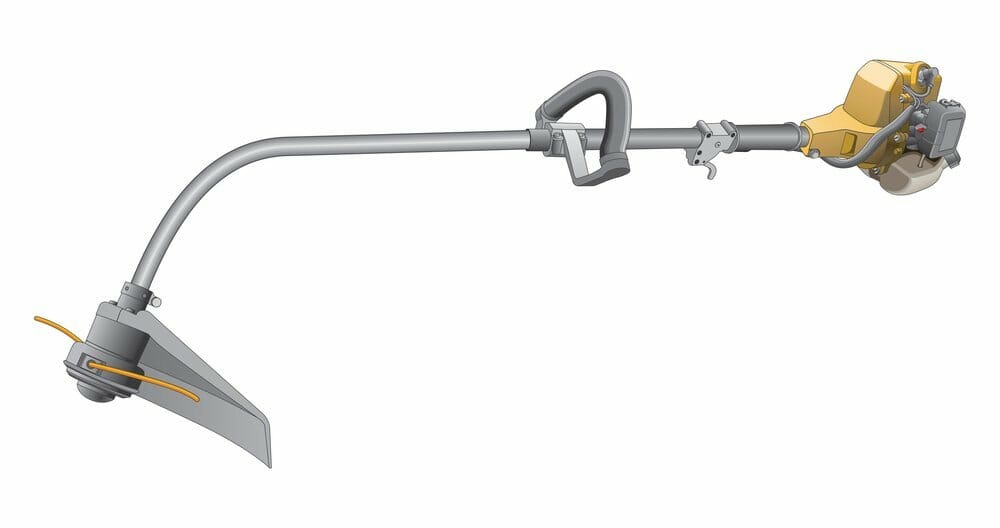

String Trimmers

There's a reason people use the phrase "grow like a weed." These pests grow fast and can soon become a problem. Use our weed eater buying guide and you'll have the best string trimmer for your yard in no time.

Hedge Trimmers

Few things are a satisfying as a perfectly-trimmed hedge. Unfortunately, nature gets in the way and shrubs continue to grow. That's why you need to buy the best hedge trimmer you can - to save time and effort.